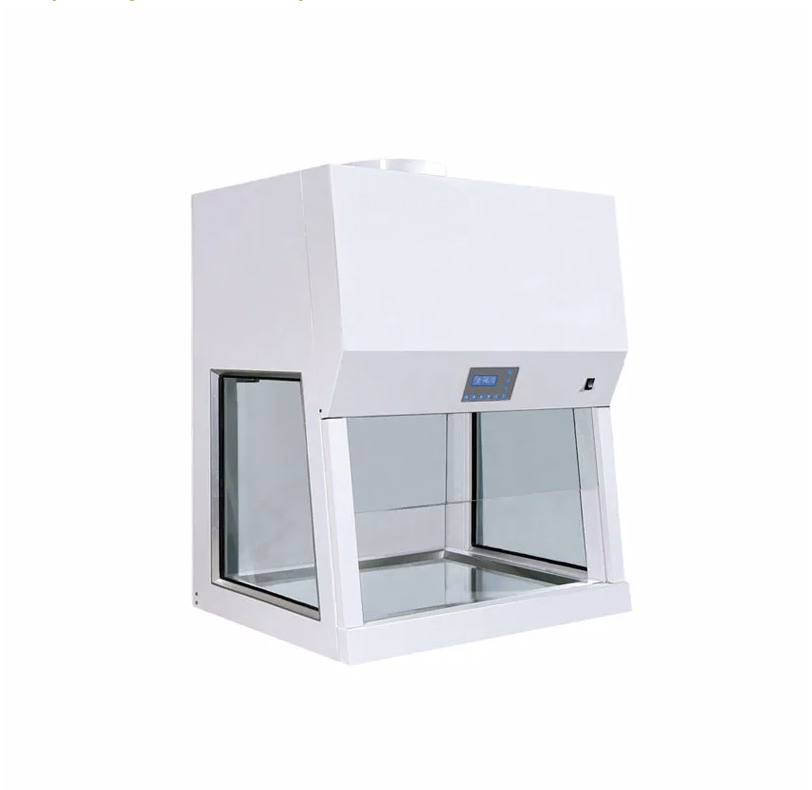

Biosafety Cabinet

- /

- China

- 15 days

- 5000pcs/monthly

A Biological Safety Cabinet (BSC), also known as a Biosafety Cabinet is mainly used for handling pathogenic biological samples or for applications that require a sterile work zone. A biological safety cabinet creates inflow and downflow of air that provides operator protection. The downflow air passes through an ULPA/HEPA filter and creates an ISO Class 3 work zone to protect samples from the risk of cross-contamination. The air exhausted also passes through an ULPA/HEPA filter prior to release to protect the environment.

A Biological Safety Cabinet (BSC), also known as a Biosafety Cabinet is mainly used for handling pathogenic biological samples or for applications that require a sterile work zone. A biological safety cabinet creates inflow and downflow of air that provides operator protection. The downflow air passes through an ULPA/HEPA filter and creates an ISO Class 3 work zone to protect samples from the risk of cross-contamination. The air exhausted also passes through an ULPA/HEPA filter prior to release to protect the environment.

Friendly Control Panel

▪Color LED screen, show the air velocity, time, fan station, HEPA filter life and alarm in real time.

Safe and Reliable, Energy-Efficient

▪DC fan and LED light make the operation power consumption save 30%.

▪Intelligent auto-supply system of imported blower ensures the change of air volume less than 10% when the resistance of filter increases 50% and enhance safety.

▪The alarm system for safe operation height is interlocked with light. At the same time light is Interlocked with sterilizing.

▪Leak detection in cabinet, no leakage at 500Pa.

▪UV light with set timer, safer and high efficiency.

Humanized design

▪ 10°sloped front make it comfortable to operator.

▪ Negative pressure and double layers chamber around ensure non-leakage, non-pollution.Demountable circular-arc armrest can alleviate working tiredness and make it easy to transport.

▪ Front window adopts hanging lifting system (Imported from Japan) and more than 5mm thickness security glass with arbitrary positioning, high stability and convenient to sterilization when it closed.

▪ Front window can be cleaned all-over, solving the problem which front window can't be cleaned inside

▪ Moveable working table with handle and support make it easier to clean collecting tank.

▪ There are two anti-splash spare sockets and four service port in the cabinet.

▪ Movable stainless steel worktable 4 liter capacity stainless steel collecting tank with below down valve, easy to collect water, cleaning and disinfection.

▪ Non-obstructive air return mode in the front suction channel .

▪ The adjustable leveling foot is without exposure thread.

Model/Item | HW-1004II | HW-1304 II | HW-1604II | HW-1804II |

Nominal Size | 1 meter(3') | 1.3meter(4') | 1.6meter(5') | 1.8meter(6') |

Filtration Efficiency | ULPA: ≥99.9995%, @0.12μm | |||

Downflow Velocity | 0.35 m/s(68.88fpm) | 0.33 m/s(64.94fpm) | ||

Inflow Velocity | 0.55m/s(108.24fpm) | 0.53 m/s(104.30fpm) | ||

Noise | 58~65 dB(A) | |||

Vibration | ≤5 μm(center of tabletop) | |||

Power Supply | AC220V,1φ,50Hz | |||

Opening Height | 200 mm | |||

Personnel Protection | A. Total colony in impaction sampler ≤10CFU./time | |||

Product Protection | Total colony in culture dish ≤5CFU./time | |||

Cross-contamination Protection | Total colony in culture dish ≤2CFU./time | |||

Max Consumption(with spare socket) | 1.65 kVA | 1.75 kVA | 1.85 kVA | 1.85 kVA |

Rated Power(without spare socket) | 0.33 kVA | 0.43 kVA | 0.53 kVA | 0.53 kVA |

Weight | 260 kg | 300 kg | 360 kg | 400 kg |

| 1004*630*630 mm | 1304*630*630 mm | 1604*630*630 mm | 1804*630*630 mm |

| 1200*795*2050 mm | 1500*795*2050 mm | 1800*795*2050 mm | 2000*795*2050 mm |

| LED 24.5 w x 1 | LED 31 w x 1 | LED 36 w x 1 | LED 36 w x 1 |

| 18 w x 1 | 30 w x 1 | 36 w x 1 | 36 w x 1 |

Lumin. | ≥900 Lx | |||

Cabinet Materials | High-grade steel and lacquered in ivory | |||

Working Area Materials | SS304 fully finished | |||

Air Direction | Top out | |||

Plug Style | Chinese Type(AC 250V/10A) | |||

Qty. of Sapre Socket | Chinese Type(AC 250V/3A) 2 units | |||

Class I Biological Safety Cabinet

A Class I Biosafety cabinet protects the operator and the environment from exposure to biohazards. It does not prevent samples being handled in the cabinet from being exposed to contaminants that may be present in room air. Naturally, there is a possibility of cross-contamination that may affect experimental consistency. Consequently, the scope and application of Class I cabinets is limited, and it is largely considered obsolete.

Class II Biological Safety Cabinet

Class II Type A2

The Class II Type A2 biological safety cabinet is the most common Class II cabinet. It has a plenum from which 30% of air is exhausted, and 70% re-circulated to the work area as the downflow.

Stated from NSF/ ANSI 49:2010, both the Class II Type A1 and Type A2 must have the positively-pressurized contaminated plenum to be surrounded by negative pressure. In case there is a leakage on the positive plenum, the leaking aerosol will be pulled by the negative pressure back to the positive plenum, and it will not leak out.

In the A2 cabinet, about 70% of air from the positive plenum is recirculated as downflow, and the remaining 30% is discharged to the lab through the exhaust filter.

Class II Type B1

The Class II Type B1 biological safety cabinet has a common plenum from which 70% of air is exhausted, and 30% re-circulated to the work area as the downflow. This cabinet also has a dedicated exhaust feature that eliminates re-circulation when work is performed towards the back within the interior of the cabinet. Toxic chemicals employed as an adjunct to microbiological processes should only be allowed if they do not interfere with work when re-circulated in the downflow.

Class II Type B2

The Class II Type B2 biosafety cabinets are suitable for work with toxic chemicals employed as an adjunct to microbiological processes under all circumstances since no re-circulation occurs. In theory, Type B2 biological safety cabinets may be considered as the safest of all Class II BSCs since the total exhaust feature acts as a fail-safe in the event that the downflow and / or exhaust HEPA filtration systems cease to function normally. However, Class II Type B2 biosafety cabinets require large laboratory spaces due to their installation system and will require elaborate ducting works.

Class III Biological Safety Cabinet

Class III biological safety cabinets are suitable for work with microbiological agents assigned to biosafety levels 1, 2, 3 and 4. They are frequently specified for work involving the most lethal biological hazards.

Work is performed through glove ports in the front of the cabinet. During routine operation, negative pressure relative to the ambient environment is maintained within the biosafety cabinet. This provides an additional fail-safe mechanism in case physical containment is compromised. On all Class III BSCs, a supply of HEPA filtered air provides product protection and prevents cross contamination of samples. Exhaust air is usually HEPA filtered and incinerated. Alternatively, double HEPA filtration with two filters in series may be utilized.